In its report, ‘Food tech: technology in the food industry’, ING found that pressure from retailers for manufacturers to create larger volumes of food at low prices and calls from consumers for food to be produced safely and sustainably sparked the adoption of new technologies such as robotisation and digitalisation.

Technological advances

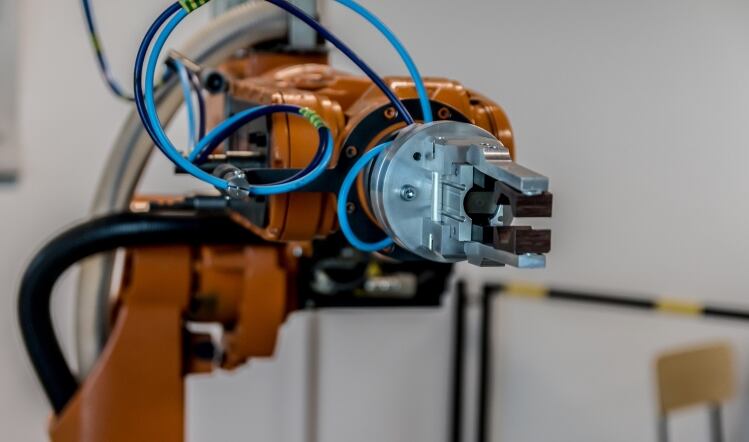

Advances in gripper and image recognition technology have allowed robots to operate in more challenging conditions prohibitive to humans – extreme heat and cold – which has simultaneously reduced the risk of contamination. This has allowed producers to comply with much stricter food safety requirements.

ING also reported an increase in producers adopting digitalisation into their supply chains to make their planning processes more efficient and to predict supply from farms, leading to a better match between supply and demand. The benefits also included transparency from farm to fork.

“Consumers and society expect healthier and more sustainable food, while food manufacturers want to make production as efficient as possible”, explained Thijs Geijer, senior economist at ING. “The use of robots and data technology can serve both.”

Impact on labour

Commenting on the impact that robots and digitalisation would have on the labour market, Geijer added: “Some jobs will disappear, others will change and new jobs will be created. That’s why investment in technology should go hand in hand with investment in human capital.”

Meanwhile, the future of food production in the UK will be defined by the adoption of robotics and innovative new technology to help address the “productivity challenge” faced by producers, according to a new report for the National Farmers Union.

The report, The Future of Food 2040, speculated that driverless electric vehicles, remote sensors and robotics had the potential to remove many manual jobs in the agriculture sector and create greater precision and efficiency.