The current economic outlook may be far from certain, but there’s no doubt that meat processors have moved on from the cautious years that followed the financial crisis of 2008.

Despite trailing markets such as North America, GEA Group says investment in equipment is growing at about 2% year on year in Europe. As well as the need to replace existing machines, it suggests additional kit aimed at increasing capacity and line efficiency while at the same time boosting automation are the main growth drivers.

Other equipment suppliers draw similar conclusions. “From what we’ve seen, [investment has] mostly been focused on improving efficiency and effectiveness of cutting – but also in automation, reducing the number of operators required to support the production processes,” says Huw James, managing director at Atlantic Service Company.

The ongoing drama around Brexit continues to be a concern for most businesses, but along with consolidation, fears over labour shortages are helping to boost investment in new cutting, slicing and dicing equipment. Faced by the prospect of a dwindling workforce, manufacturers are seeking greater automation as sites consolidate into more streamlined operations.

“We see an increasing use of automation in the processing industry, particularly with large-scale processors,” says Thurne president Peter Jongen,

Thurne operates in case-ready meat portioning where, traditionally, a great deal of manual intervention is required. This includes transferring primals from freezer to press or directly into the portioner at the beginning of the process, and manually correcting weights to achieve optimum results for fixed weight packs – particularly for packs with low slice counts.

“We have been working with our Middleby Food Processing sister companies to devise a fully integrated case-ready meat in-line portioning and packing system that requires minimum intervention with maximum results in terms of yield and on-weight performance,” Jongen explains.

The Thurne one case ready Portioner uses an innovative scan-in-track system that includes the capability to produce fixed-weight packs with a set slice count, including single-slice portions. The Portioner’s continuous feed system, combined with an innovative end-piece gripper, is said to maximise product yield and offer the capability to produce up to 100 case-ready packs a minute.

Marel’s Poultry Automated Nugget Line, meanwhile, reduces reliance on manual labour by combining two I-Cut 22 machines with its SpeedSort, SingleFeed and StripPositioner modules. Manual operators are only required for quality control.

“Compared to a conventional, manually-fed portioning machine, the Automated Nugget Line can save at least two people per shift, while increasing throughput by up to 30%,” says Morten Dalqvist, product manager for portioning at Marel. “The line will produce whole muscle nuggets, cut uniformly to each customer’s fixed weight and dimensions. Giveaway is among the lowest in the market.”

No need to crust-freeze

A further innovation by Multivac UK reduces labour by removing the need to crust-freeze product before cutting. “With the current slicing machinery available in the UK market, producers have to crust-freeze product before slicing to an ensure optimum cutting performance, which can have a detrimental effect on the product,” says Martin Wareham, TVI product manager at Multivac UK.

“Crust-freezing can be both labour and energy-intensive, as the product often requires double handling and extra power. These two resources are both becoming increasingly expensive and, in the case of labour, difficult to find and retain. A lot of producers use traditional chamber-style dicers for bulk dicing, but these machines cannot provide the individual cube weight and dimensions that a TVI machine can deliver.”

Multivac supplies the compact GMS 520 portioning machine from TVI, which offers producers accurately portioned pork or beef steaks at a fixed weight, as well as cube size/weight portions.

“Like all TVI portioning machines, the portioner can shingle, stack or individually present finished steaks, which reduces the labour required to format the slices ready for packaging, helping to create an automatic ‘portion to pack’ system upstream,” says Wareham.

One customer recently purchased a TVI GMS 520 due to its flexibility to go from injected pork loin steaks to fixed cube weight and size on dice, ready for an automated kebab-making system, Wareham adds.

As well as reducing labour, processors expect the latest automated lines to improve the safety of those workers still required to operate them.

“One of the prime areas of focus in cutting, slicing and dicing is currently bandsaws, as abattoirs and cutting operations – particularly their health and safety policies – come increasingly under the spotlight,” says Richard Nethercot, group divisional manager – low risk, Butchery Division at Interfood.

“Safety is critical at a time when labour shortages are highlighting the heightened potential for injuries to unskilled workers. These same unskilled workers are also potentially reducing profit margins, as their lack of experience in cutting meat leads to imprecise cuts and variations in portion size.”

Interfood has responded to these issues by introducing the PW (Precision Weight) saw from Astech, a continuous automatic bandsaw with integrated weight control.

The bandsaw can handle frozen meat, fish and fresh bone-in products, operating continuously during loading, with its integrated scanning system allowing precise slicing to pre-determined parameters of weight or thickness.

“High-quality cuts are generated through precise speed adjustments while, as a fully enclosed machine with a user-friendly interface with versatile programming, safety and ease of operation are ensured,” says Nethercot.

While Interfood also supplies the BladeStop system, designed to allow operators to get close to the blade in a safe way, “there is also a significant demand for completely automated systems,” says Nethercot. “And with the introduction of this precision weight control option, we can now offer a system for whichever route a business wants to take.”

Specialised offers

Another trend driving investment, highlighted by Atlantic Service Company, is a movement towards specialised customer offerings. “The challenges of cutting product that is constantly being differentiated requires a deeper understanding of our customers and more integrated relationships,” says James.

Pork prices up, amid ASF fears

UK pork producers are receiving a boost on the back of the impact of African Swine Fever (ASF) on the Chinese market.

The average price for European pork between May and July rose 18% against the previous three-month average, far exceeding previous forecasts, according to procurement company Beacon.

Beacon’s supplier Brakes suggests that 30–50% of Chinese pig farms have been affected by the outbreak, which in turn has increased pig prices across the globe.

However, fears are mounting that ASF will soon reach the UK after farming minister George Eustice admitted an outbreak in the country was likely within 12 months.

Writing to the National Pig Association (NPA), Eustice said the UK threat level was medium, meaning an outbreak was “expected within a year”. The NPA called for a “more robust approach” from Government and the UK port authorities.

Atlantic supplies blades to the meat, fish, bakery and processed meat and cheese sectors. “No matter which machines are being used or which product is being cut, we can supply a blade and adjust its characteristics to match, which is behind the significant growth of the company over the last five years,” James suggests.

“Working in partnership with customers, we have developed machines for them, many of which have grown from being bespoke to becoming part of our standard product range and creating some great long-term opportunities.”

First and foremost, producers are looking to respond to customer demand by creating the most attractive products possible, says Dalqvist at Marel.

“Presentation should be natural with a slanted cut,” he claims. “Portioned products – such as butterflies, fillets, tenders, strips, dices, nuggets and popcorn – should be neatly trimmed and should look good in a tray pack or on a plate.”

According to Dalqvist, versatility is vital as products need to be suitable for sale in supermarkets, restaurants, fast food outlets and in further processed products.

“These days, food safety is a major concern for poultry processors,” he says. “Filleted and portioned products must be completely bone-free. For a more efficient and productive process, cutting, slicing, and portioning operations need to be done both more speedily and with a high degree of automation.”

Processing capacities are increasing all the while and products often have to be cut to a fixed weight and/or shape, Dalqvist argues. “To maintain a profitable process, any automatic equipment must do its job extremely accurately, so that the need for manual trimming and giveaway are kept to an absolute minimum.”

Maximising yield

With manufacturers operating to tight margins, maximising yield is always a goal of any investment in new equipment.

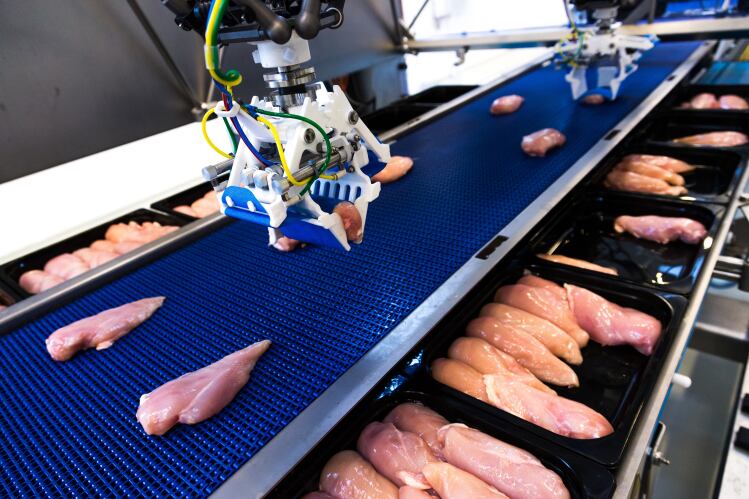

Marel’s ‘robot with a knife’ system combines its I-Cut 122 machine and a RoboBatcher Flex, to integrate cutting, batching and packing with the aim of minimising giveaway.

The RoboBatcher’s high-performance gripper facilitates the slick tray packing sought by supermarkets, with its vision system orientating individual products to be picked up in the same way.

“The new grippers don’t drop products into the tray, as the resulting bounce would cause a loss of control over how products land,” says Dalqvist. “Instead, the gripper moves to the bottom of the tray to release product at exactly the right spot. The jaws of the gripper open no more than necessary, which is particularly important for the last product in a tray.”

Another innovation by Marel, the new I-Cut122 TrimSort, is tailored towards manufacturers looking to avoid giveaway when handling heavier birds.

“Broilers and the products cut from them are getting steadily bigger all over the world,” says Dalqvist. “These cut products often no longer fit into a tray and have to be portioned, an operation resulting in more meat being cut off. These off-cuts, which in the past often ended up as low-value mince, can now be turned into a range of exciting products that can be sold for a good price.”

The TrimSort can be integrated into the I-Cut 122 portion cutter to offer a synchronised cutting and trim reject process within a compact frame no larger than the I-Cut 122 itself.

Enabling the portion cutter to remove much smaller pieces of trim – 5g rather than 25g – without the module, means TrimSort has the highest success rate in the industry for separating trim from the main product, says Dalqvist.

And such precision allows portion cutting to be extended to products previously trickier to handle, such as breast fillet, tenderloin, thigh fillet or leg meat.

“Unnecessary giveaway is avoided,” he says. “All portioned meat pieces will be cut precisely and consistently to a given target weight. Packing becomes both easier and more accurate. Processors no longer have to be afraid of overweight trays eating into their profits.”

Offering application-specific slicing equipment allows equipment manufacturers to optimise yield and throughput, says Jongen, highlighting Thurne’s expertise in bacon slicing.

“Accuracy is critical and on-weight performance, as well as low giveaway, are key to profitable performance,” he says.

“We know that bacon has strong regional variations and specific market requirements, and our equipment allows for these subtle differences to deliver the best results at low operating cost. Our IBS1000 Bacon Slicer is optimised for the slicing of back bacon and well established within the UK and Irish bacon processing industry. Advanced gripper technology has reduced butt ends to typical low weights of 80–100g, greatly improving yields for our customers.

“The gripper also maintains maximum product control for consistent slicing quality, and sub-six second reload time makes throughput of up to 2t per hour possible.”

Thurne will unveil a new UK bacon-slicing platform in the new year, combining continuous feed with end- piece gripper technology to enhance throughput, product control and yield. A continuous feed version of the new kit, Thurne one bacon, has already been successfully introduced to the US bacon market, says Jongen.

Optimisation of yield is also said to be an asset of Multivac’s S 800 and S 1600 slicers, launched into the UK market earlier this year, following their use in continental Europe for several years. Ideal for cooked meats and cheese applications, the slicers are attracting strong interest in the UK, according to Mulitvac business development manager Phil Crozier.

Advantages of the two models include a novel blade design, again removing the need to crust-freeze before cutting, and quick product changeover. As well as increased yield, benefits include a better-quality sliced product and a best-in-class hygiene performance, according to Multivac.

One client recently trialling the S 800 reported that they had benefited from a reduction in shift requirements and significantly less labour for the same line output, says Crozier. “The giveaway and yield were at least as good as or better than their existing equipment,” he adds.

Multivac is officially launching the S 800 to the UK market at its Packaging and Processing Forum, held in Swindon from 9–10 October.

Using GEA’s OptiScan 600 pre-scanning system for raw ham products in combination with its DualSlicer II, meanwhile, is said to enhance slicing and portioning quality, as well as yield.

Recent installations by GEA include a major Irish bacon processor, which installed a complete line comprising its OptiScan 600, DualSlicer II 1200, Check 4000 weigher, PreDiverger, ShingleLoader 600 and PowerPak. Following the investment, the processor reported high yield and very low giveaway in combination with high output and line efficiency, says GEA.

Fresh and grilled chicken remain a cut above

Reflecting the buoyancy of the cutting, slicing and dicing equipment market, sales of fresh and chilled chicken cut continue to grow.

Fresh chicken cut production in the EU totalled 6.8mt in 2018, up 7.8% against the previous year, according to the IndexBox report, EU – Fresh Or Chilled Cuts Of Chicken – Market Analysis, Forecast, Size, Trends And Insights.

Based on 2018 figures, the report says fresh chicken cut consumption increased by 15.2% against 2015 indices and is expected to keep growing in the near future. The UK recorded the third-highest volume of fresh chicken cut consumption in the EU in 2018 (911,000t), behind the Netherlands (1.1mt) and Poland (947,000t).

Together, the three countries had a 45% share of total consumption. Similarly, the highest levels of fresh chicken cut per capita consumption was registered in the Netherlands (64kg per person), followed by Poland (25kg per person) and the UK (14kg per person).

The revenue of the fresh chicken cut market in the EU was estimated to be $18bn (£14.4bn) in 2018 – an average annual increase of 7.1% since 2007. The UK contribution was $3.7bn (£2.96bn), the highest in the EU.

In 2018, the fresh chicken cut export price in the EU was $2,466 (£1,976) per tonne, surging by 11% against the previous year. Long term, however, prices continue to indicate a mild downturn, having peaked at $3,023 (£2,422) per tonne in 2008.