Reading between the lines, these priorities are not just about delivering for customers, but also about increasing efficiency and minimising waste – no surprises at a time when costs are soaring.

With the resurgence of face-to-face exhibitions as pandemic restrictions ease, equipment suppliers are preparing for shows such as Anuga FoodTec (26-29 April in Cologne) and IFFA (May 14-19 in Frankfurt) to showcase advances reflecting these demands.

MRMK's InfinitEdge blade coating tech

One such supplier at the cutting edge of development is MRMK, which this year is whetting the trade’s appetite with its patent-pending InfinitEdge technology, due to be revealed at Anuga FoodTec.

Based at Dinnington in Sheffield, the heartland of the UK steel industry, the company is playing its cards close to its chest at this stage, no doubt partly to build anticipation. What it will say is its proprietary technology ‘creates blades of exceptional sharpness and exceptional endurance’ using ‘groundbreaking’ blade coating technology.

Having designed, manufactured and supplied machine knives for food packaging and processing for decades, MRMK makes its blades from high-quality hardened stainless steel sourced from only ISO 9001:2008-accredited suppliers. It caters for a comprehensive range of product categories, from packaging knives and thermoforming machine knives to tray seal and converting knives.

MRMK boldly claims its latest innovation is designed to outlast all other blade coatings when cutting non-ferrous materials such as aluminium, plastics and food materials.

MRMK sales director Jack Bailey says a big drive behind boosting blade quality is to limit the downtime caused by having to replace failing blades. “Our engineers created the InfinitEdge to directly address this challenge, developing a blade coating technology that improves blade performance, the lifespan of the blades and ultimately bigger cost savings over time for our customers.”

Ultrasonics

The quest for precision, consistent quality and waste reduction MRMK is addressing is fuelling renewed interest in ultrasonics, particularly for convenient pre-portioned products, says Telsonic Ultrasonics.

Keeping pace with demand for such products poses problems for manufacturers, says the company. Mechanical cutting systems traditionally used for slicing, dicing, and portioning are challenged when used on soft, sticky, or delicate products.

Traditional mechanical blades can cause issues ranging from smearing and cross-contamination to the crushing of more delicate products.

However, Telsonic says ultrasonics, which uses energy from microscopic vibrations of a blade to pass easily through materials, tackles many of these challenges as well as boosting efficiency, productivity, higher yields, and product quality.

Concepts range from dedicated automation systems incorporating one or more ultrasonic blades, to highly flexible multi-robot systems, capable of producing cuts in different positions and orientations (see boxout below for case study).

As a result, a growing number of items such as sandwiches, cheesecake, gateaux, cheeses, and a host of other products, are being successfully cut and portioned automatically using the process, says Telsonic.

According to the business, ultrasonics provides consistent portion control and eliminates crumbs – important considerations for customers viewing products on the shelf. Manufacturers also increase yields, due to consistent cuts, and the ability to slice very thinly.

Productivity gains are achieved through the speed of the process, and as cutting sonotrodes (the tools that create ultrasonic vibrations) do not face the same contamination problems as traditional cutting blades, uptimes are higher.

It is also possible to introduce automated cleaning cycles on dedicated cutting systems or robot-based systems if desired, either by dipping the sonotrodes in a cleaning bath and activating the ultrasonics, or by jet washing within the machine.

In recent years, sonotrodes and their associated converters can easily be mounted to multi-axis robot systems, which has improved uptake of the technology, Telsonic claims. The development of extra-wide sonotrodes, up to 800mm, by the company has helped grow take-up, it says.

Double-length yet lightweight ‘T’ sonotrodes driven by Telsonic’s flexible compact 20 and 35kHz MAG - S type generators enable the use of smaller robots, creating a more compact system, taking up less floor-space, it adds.

“We work closely with both end users and system integrators throughout the UK to ensure that we can deliver the optimum solution for any specific application which they may have,” says Telsonic UK sales manager Martin Frost.

“The combination of our expertise in ultrasonic technology and the technical innovation, in terms of the solutions which can be offered, has led to the development of a comprehensive range of ultrasonic based food cutting and portioning solutions.”

Thurne-Middleby's Portion X

Of course, ultrasonics isn’t everything and uniform portioning can just as easily be achieved in some categories through other approaches.

One example of such innovation is veteran machine supplier Thurne-Middleby’s newly-launched Portion X meat portioner.

Debuting at IFFA 2022, it’s developed for high-volume case-ready beef and pork processing. It uses new product conditioning and scanning technology for consistent handling of variable product and optimised portioning performance for weight control and maximum yield.

Multi-dimensional, patent-pending active forming technology enhances the portioner’s ability to gently form primals of variable size, eliminating the need for dedicated forming moulds for each primal.

Only a small number of change parts is needed to handle a variety of primals within a size range, limiting changeovers, Thurne says.

The gentle blade action of the orbiting head is designed to produce high-quality, evenly-cut portions, from individual and layout steaks to clearly-defined shingled groups of thinner cuts such as minute steaks.

The steaks and shingled groups produced are ready for packing with high on-weight rates, eliminating the need for manual collation and styling, and minimising rework required to achieve target pack weights.

“PortionX was designed to increase production capacity with the same number or fewer operatives,” explains project manager Adrian Neave. “Additional benefits of the reduced requirement in manual handling could be a more compact overall line footprint and improved shelf life.”

Weber

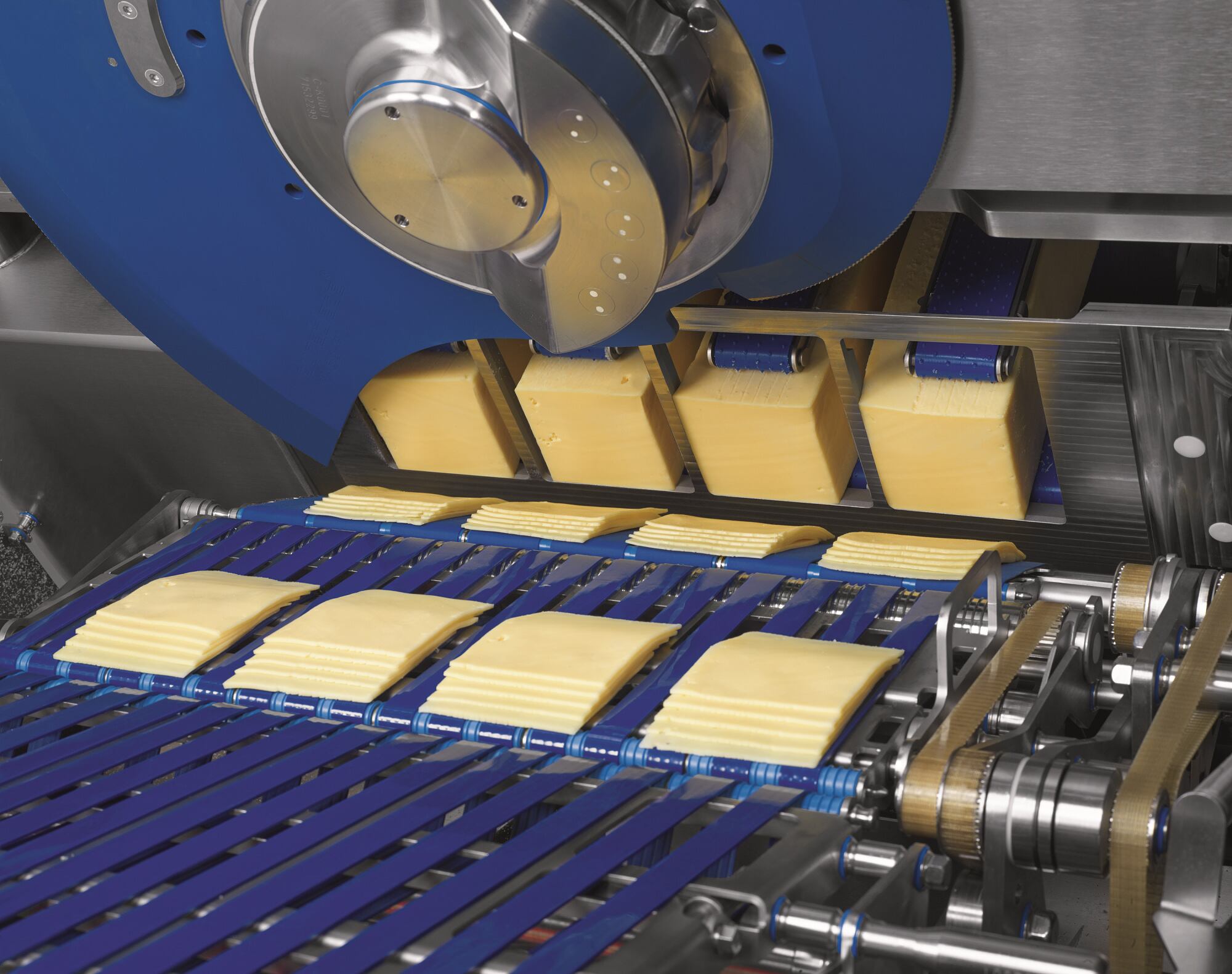

IFFA will also host innovations from Weber’s Textor and Weber brands.

Weber aims to show how holistic product preparation, processing, and packaging can increase cost-effectiveness and how the intelligent networking of all line components and the use of line data can optimize production.

The company says the solutions it will demonstrate will offer added value in every processing step and generate more output from input for food producers.

Digital products and services are as much a part of the holistic approach as innovative technology. Food processing companies will benefit from greater transparency, effectiveness, and service thanks to new digitization concepts that visualize lines and processes at a glance.

Weber says its range of derinders, skinners, and defatting machines will include innovations for tradespeople, small and medium-sized businesses, and industrial applications.

Highlights will include innovations in the areas of safety and user-friendliness, a new industrial derinder with a more user-friendly and hygienic design and the development and expansion of automation for loin defatting.

GEA CutMaster Generation 3 bowl cutters

Of course, in a sign of the times, equipment suppliers historically supplying meat manufacturers are also extending their reach to cater for the growing demand for plant-based foods.

Also at IFFA, GEA will launch its CutMaster Generation 3 bowl cutters, which in addition to sausage, poultry, fish and cheese, can be turned to plant-based, vegan and vegetarian applications.

According to the business, the machines unite customer-driven technology advances, including integrated AC drive, and improved hygienic design.

They incorporate GEA’s new Performance Plus predictive and preventative maintenance system, which uses advanced online condition monitoring and helps food processors to monitor performance, plan maintenance schedules, cut costs, improve uptime and maximize productivity.

Interfood

Separately, Interfood’s equipment offering for meat-free production requirements also encompasses cooking, slicing and packaging systems, along with the Afogrill and Afoflame systems which provide a roast or flame-grilled finish to meat-free as well as meat-based products.

In many cases this allows the creation of full line systems alongside its end-of-line inspection and case packing systems. Andre Clareboets, divisional manager at Interfood slicing, says: “Recent projects in which we’ve been involved include the production of both sliced vegan cheese and cooked meats through fully integrated lines with the Weber wePACK Thermoformer packaging machine and Weber’s high speed slicing solutions at the heart of the systems.

"These are complimented by package inspection from Sparc systems and case packing machinery from Buhmann, all supported fully by our in-house project department.”

Clearly, the reintroduction of the trade show season and demand for consistent product quality, efficiency and waste-reduction mean the cutting, slicing and dicing market is as innovative as ever.

Combining ultrasonics and robotics in cheese cutting

Elliptical Design was approached by a leading UK cheese manufacturer to create a cutting system to help reduce waste and increase throughput. Cheese is traditionally hard to cut in manufacturing. Cutting with a knife can result in breakage, and even the drag of the knife can cause damage.

Ultrasonic cutting provides a method for manufacturers to complete product-worthy cuts, without damage. Precise cuts when portioning cheese do not just reduce waste, but also meet quality checking and legislation related to food quantity.

To deliver this precision, Elliptical Design brought industrial robots into the process, using machinery from TM Robotics alongside robotic pick and place applications

Elliptical Design brought a TV1000H 6-axis industrial robot from TM Robotics in to lift ten-kilogram pieces of cheese and move them to a weigh station, and then a cutting station, where they are cut in half using ultrasonics.

“For us, all equipment needs to be food grade,” explains Phill Thompson, managing director of Elliptical Design. “Next, we look at the functionality, speed and precision of the robot. Our projects are about improving efficiencies for our customers, so we need robots like Shibaura Machine’s, that can bolster the improved precision delivered by our own ultrasonic technology.”

Before the project, the manufacturer’s production process was almost entirely manual, and took four to five days to produce the quota of cheese needed weekly. With Elliptical Design’s bespoke ultrasonic cutting system and Shibaura Machine robots, the same production quotas are reached in just two days, due to increased throughput and reduced waste.