European food safety laws prioritise traceability to ensure the safety and quality of food products throughout the supply chain. The General Food Law, applicable in the European Union (EU) and UK, requires food businesses to establish and maintain procedures for traceability. This facilitates the rapid identification and removal of unsafe food from the market to protect consumer health.

Food safety in manufacturing

Much is at stake for manufacturers that fail to guarantee safety in food production, including loss of customer confidence and reputational damage. However, addressing food safety in food processing facilities is not easy. Investments of time and money, processes and equipment, as well as changes to culture and awareness among workers on the shop floor are required.

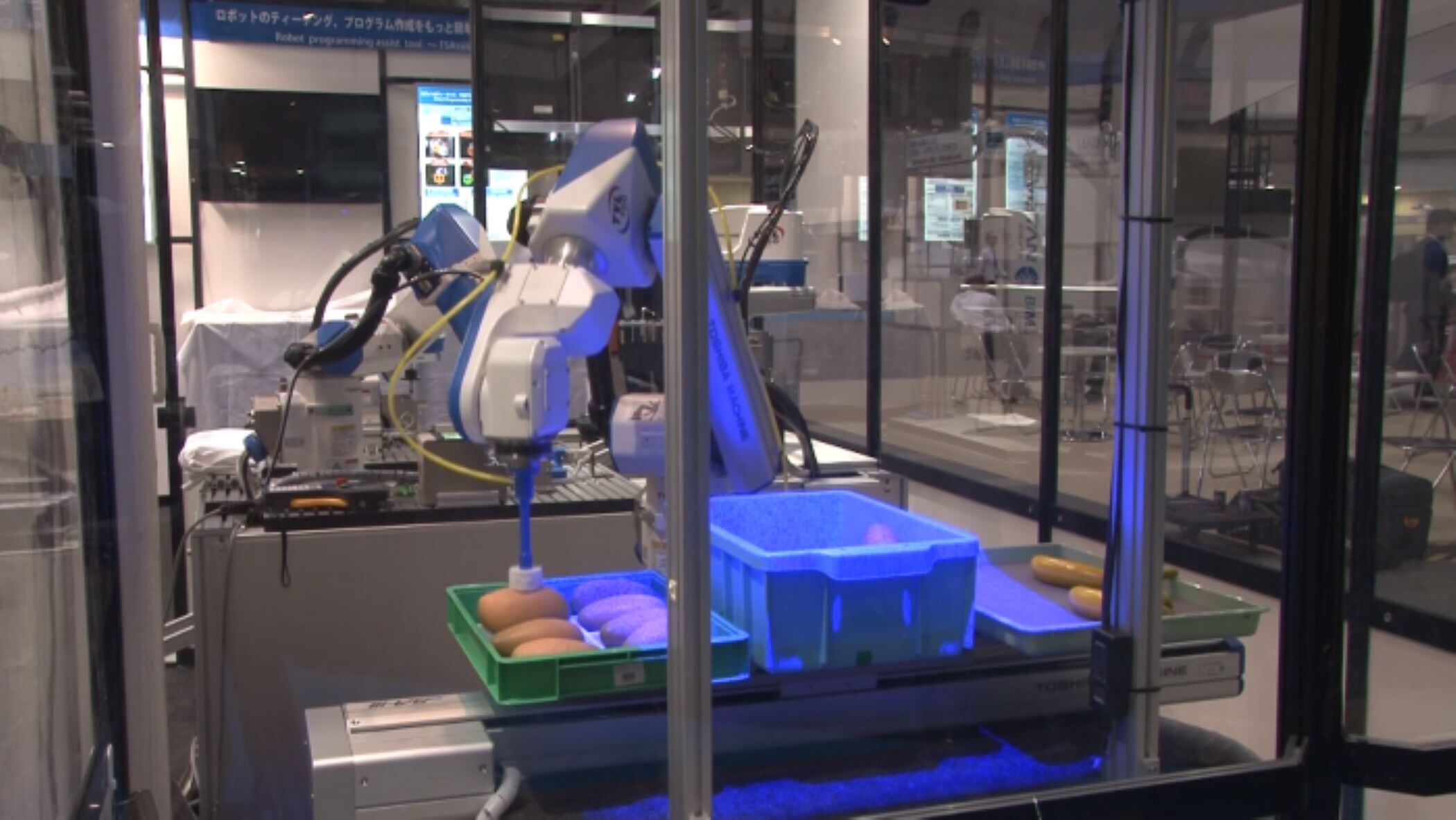

Fortunately, automation offers a solution to these myriad challenges, particularly advanced robotics. In 2020, the EU received the largest share — 27 per cent — of newly installed robots in the food manufacturing sector, reports Internationale Nederlanden Groep (ING). Robots not only keep human workers out of uncomfortable or unsafe environments, and free from injury, they can also eliminate the potential for cross-contamination. Robots are especially effective in repetitive tasks like casing, packaging and bin picking that involves gripping, moving or placing different food products.

Eyes for robots

This brings us to a major benefit of robotic systems: sorting and separating quality products from those that may be inferior or even unsafe. Robot-assisted quality-sorting is one of the most effectively ways to improve traceability systems in food manufacturing environments. This is supported by the latest Industry 4.0 sensors and advanced vision systems — that’s the eyes of robots that allow them to assess light, temperature and proximity to other objects in the surrounding environment.

Of particular importance are 2D and 3D vision systems. Blind robots — or those that operate without vision systems — are often deployed to complete simple repetitive tasks. Whereas robots with machine vision react intuitively to their surroundings. In other words, these robots are truly autonomous and, when programmed effectively, can identify and remove unsafe foods from production.

A clear reading

With a 2D system, the robot is equipped with a single camera. This approach is better suited for applications where reading colours or textures is important, like barcode detection. 3D systems operate with multiple cameras and can overcome some of the errors 2D-equipped robots encounter when executing physical tasks, which would otherwise leave human workers to diagnose and solve the malfunction.

3D systems can read barcodes, check for defects such as in engine parts or wood quality, inspect packaging and inspect the end product.

The latest vision systems include Shibaura Machine’s TSVision3D system for industrial robots. The system doesn’t require complex CAD data to recognise objects and instead uses two integrated, high-speed stereo cameras to capture continuous and real-time 3D images. The software can recognise any object that’s positioned in its field of vision, even for non-uniform products like bananas.

Take the example of Elliptical Design, a design and manufacturing company that turned to TM Robotics to design an ultrasonic cutting system for robot-assisted quality-sorting. Developed for a cheese manufacturer, the challenge was to ensure that the robot was picking up cheese in the right place and being able to put it down as accurately as needed. However, a margin of error was created by the cheese’s softness and unusual non-round shape.

Using their partnership with Shibaura Machine, TM Robotics’ engineers found the right algorithm in the vision program to ensure the robot could pick the cheese accurately. The result was automated quality-sorting with improved efficiency and reduced waste.

This example shows how robot assistance can allow for faster identification and rapid removal of inferior quality foods. What’s more, with industrial robots and advanced vision inspection technologies, like Shibaura Machine’s TSVision3D system, manufacturers quickly eliminate contaminated foods from production lines and, in doing so, help keep Europeans safe from the ill, or even fatal, effects of food poisoning.

Meanwhile, machine vision automation can help confectionery manufacturers and packers to combat unskilled labour shortages, according to Scorpion Vision.