While the main focus for sustainability goals in food and drink has been on packaging, according to Multivac, there is a lot more that manufacturers can do throughout the processing and packaging chain to contribute to their sustainability story.

While the pressure is on, both from a legal and consumer perspective, for food and drink brands to achieve and exceed expectations on sustainability, it’s a confusing scene out there in the UK market.

A survey by Statista in August 2021, revealed that 13% of UK respondents would be willing to pay more than 10% extra for sustainable food1 and this is increasingly being demanded by the younger generation in particular. Meanwhile, the upcoming extended producer responsibility legislation (EPR), taking effect from 1 January next year, will tighten the rules on packaging and require compliance from relevant food and drink firms.

Materials: reduce, replace, recycle

The big push to reduce plastic, which really began around five years ago, was ramped up two years ago when the Blue Planet II series aired the impact of marine plastic pollution. “Everyone wanted a panacea. They wanted to get rid of plastic, but not reduce shelf-life or have any on-cost or invest in any new kit,” says Elliot Chrisp, materials business unit manager at equipment supplier Multivac UK. “It wasn’t possible… or rather, it could be possible but you had to compromise on one of them.”

Pressure from brands’ marketing departments and from supermarkets, both responding to expectant consumers, created the perfect storm and the battle was on to satisfy those demands but create a balance that meant products continued to be protected through the supply chain and were afforded a reasonable shelf-life. In some ways, the pressure to reduce plastic became a race to the bottom.

By nature, recycled materials need to go mono and when a brand has traditionally used two polymers in its packaging, then the transition is not necessarily straightforward – as there was always a reason for those two different types of plastic in the first place, notes Chrisp.

A major problem that suppliers are now facing is the supply and demand of alternative packaging materials. While plastics can be replaced with additives such as EVOH (ethylene-vinyl alcohol copolymer -a clear, glossy thermoplastic copolymer) for barrier properties, the demand for EVOH has soared, with the result that supply has been restricted, with everyone on allocation. “I don’t think the demand for EVOH would have gone through the roof if we hadn’t had this push for a mono approach,” says Chrisp, who suggests that the supermarkets have pushed the market down the mono route.

Recycled polyester (rPET) flakes are another issue, says Chrisp. As some of the multinational soft drinks companies are going 100% rPET on their bottles, it eats up the industry’s trade flake. And a lot of rewash and regrind in the market can cause quality problems, with ensuing wear on equipment.

According to Chrisp, there is no silver bullet polymer out there that will magically transform this situation. “We have to get better at recycling and attitude, with the government needing to step in with legislation on recycling. Once we have much better capacity and investment for recycling in the UK, we won’t need that silver bullet polymer. We’ve got good plastics, but we don’t know how to use, reuse and recycle them in an efficient way.”

However, there is light on the horizon. During the recent Covid pandemic, people began to look at the whole situation more pragmatically, says Chrisp. “Product protection became king, along with supply simply getting through. So, for example, we’ve got a project with a client at the moment that is actually looking at extending shelf-life, while reducing plastic by 40%, which gives them two weekends’ shelf-life in a supermarket, but completely changes the pack presentation.

“That supermarket is going for it, because they see the benefits, but they are also taking a risk and ripping up the rule book on how this particular product is presented. We’re starting to see a little bit of a shift-change on compromise.”

Machinery: reducing energy consumption

However, from Multivac’s point of view the sustainability message goes way beyond materials and into all areas of production.

Chris Howard, product sales manager at Multivac UK, highlights the range of packaging solutions that drive and support sustainability. For example, Multivac's thermoforming range can save energy saving by moving away from compressed air into more servo-driven applications and electric lifting systems.

“Air is one of the big energy consumers,” he says. “If we can remove that element and replace it with a far better source of energy to make the machine work, then we can make the production line more sustainable.

“For example, a lifting system on a thermoformer has typically been driven by pneumatic cylinders. We’ve changed that to an electric lifting system. And, with many customers now installing wind turbines or solar to run their factories, and moving away from pneumatic air via the green energy the factory is producing, we can then claim the machines are sustainable and, we believe, the most sustainable, efficient thermoformer on the market.”

One customer who made an initial investment to convert from an airlifting system to an electric system has had an extremely quick return on investment, purely because of the energy saving and productivity, notes Howard.

The other way in which Multivac can help customers with efficiency is through its technical team of 55 regional service technicians, adds Howard. “Efficiency checks on the equipment can highlight a number of machinery performance indicators, and having regular maintenance reviews can ensure equipment is optimised and, therefore, more sustainable as a result.”

Machinery: processing equipment

Meanwhile, Multivac UK’s processing business unit manager Liam Smith has been looking at the use of CO2 in manufacturing and analysing where savings can be made. “There are lots of different ways to manufacture the same product, as we see on different customer sites,” he says. “It’s not just about the plastic and the CO2 reduction within a pack, it’s how we manufacture what goes into it that also counts.”

He has been working with a customer who uses a lot of CO2 to produce and cool their beef and mince for burgers, he reveals. “There are some really big numbers that came out of switching from CO2 mixing to bring the temperature down,” he reveals. “For example, we can supply a Laska SuperGrinder that’s capable of handling frozen blocks and fresh meat, while keeping the temperature where it needs to be. There is no gas consumption used whatsoever, and that’ll save the customer large costs on gas alone, but then also saves CO2 going into the atmosphere.”

Working with Elliot Chrisp on the materials side, Smith is looking at producing a pack that’s much cheaper to manufacture. “The quality is good and the sustainability far better,” he says. “We can take a customer from using a tray-seal pack with, say, 50% gas going in, to something that’s a full vacuum pack, removing the seal even further. Being able to combine processing and packaging to get the ultimate pack is a double whammy. Seeing the bigger picture gives the ultimate benefit for the customer.”

Removing plastic from the line

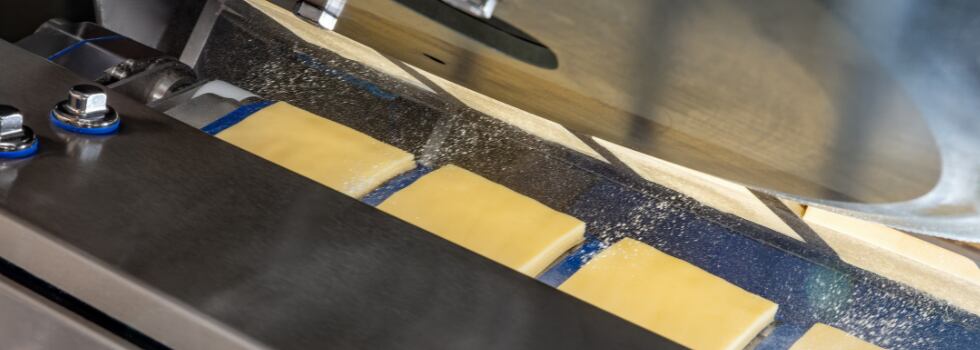

Slicing is another area where sustainable moves can be made, adds Lewis Pascoe, slicing product manager at Multivac UK.

“Generally, people don’t look at the slicer, as that is where money can be saved in terms of yield and giveaway,” says Pascoe. ”However, Multivac's Slicing team in Germany has been looking at ways we can make the machine more sustainable – for example, the gripper system is completely different to some of our competitors’ machine as we don’t use air on the grippers instead - it’s a contained system.

“Plus, in terms of mature cheese, for example, companies have tended to use a plastic interleave between each slice. We worked out that, if you were running, at medium speed, 500 cuts on a three-lane slicer, that equates to up to 180 million pieces of plastic a year - that's upwards of 40 tonnes of plastic that can be saved by adding a spray interleaver, which provides the same effect as the plastic. We have proven this with different types of oils – and you can still peel the cheese or cured meats away without damaging the slice.

“My figures revealed that there was an 85% saving or £3,000 per day saved on plastic interleaving.”

The company’s Sustainable Liquid Interleaving spray system can also be used as a marination tool or flavour enhancer, he notes, which gives an added effect for customers who require it and can also remove an additional piece of equipment.

Service optimisation

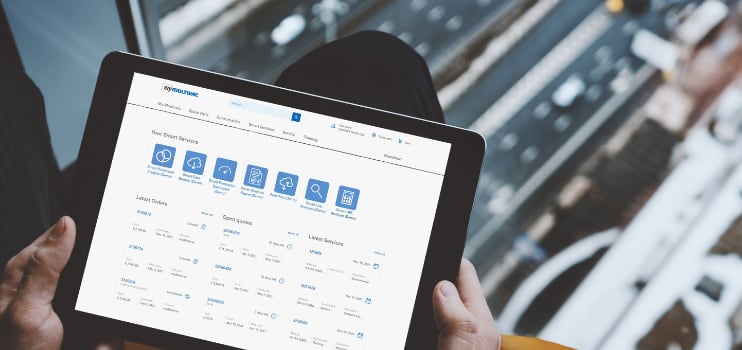

Meanwhile digitalising the whole production process clearly has benefits in that it allows users to analyse machine efficiency, downtime and repair. The company’s system portal, My-Multivac, allows customers to order parts and connect to smart services where they can log on to review the efficiency and maintenance needs of their machines.

Multivac has combined all these elements of sustainability into its Right Pack consultancy service, headed up by Elliot Chrisp, which advises customers on the best methods of achieving sustainability in their factories right across the production process.

Multivac UK has also recently launched 'The Multivac Podcast' which discusses the above topics, and answers popular questions within the industry. The next podcast is due to air next month and will focus on materials, machinery and sustainability.

And the company will be running a webinar on 6th December in association with Food Manufacture. Watch this space for more details.

To find out more about Multivac can help with your sustainability drive, contact Chris Howard on chris.howard@multivac.co.uk.

To see the company's Slicing Interleaver in action, see the video below:

Source

1 https://www.statista.com/statistics/1291366/willingness-to-pay-more-for-sustainable-food-uk/