Complete Package

Complete Package: two-week packaging trend snapshot

Extended Producer Responsibility (EPR) consultation hots up

With only a week for industry to respond to the Government consultation on EPR for packaging waste, the UK’s largest compliance scheme, Valpak, has released detailed modelling for a range of the proposed options.

Amid growing alarm at the cost of the scheme to suppliers, and fears costs will have to be passed on to consumers, James Skidmore, head of consulting at Valpak, said: “We already knew that overall costs for producers were set to rise from £230m to £2.7bn. However, under the modulated fee system, some packaging materials will bear a greater portion of the cost.

"Valpak’s Packflow EPR breaks down the figures to forecast the impact on different materials. It also shows how responsibility and funding could be allocated through different areas of the supply chain.”

The report is the first of its kind. It incorporates data from Valpak’s Environment Product Information Centre (EPIC) database, which holds the most detailed metrics on packaging in the UK. It includes an overview of suggested EPR changes; the impact on different areas of the supply chain; possible impacts on the environment; and scenarios showing the potential scale of fee modulation, including the impact of new responsibilities for the management of litter.

The modulated fee system aims to encourage the design of more sustainable packaging. It involves higher fees for less recyclable packaging products, or for those which do not contain recycled material.

The analysis includes three modulation scenarios. One involves a flat, per-tonne cost for recycling and disposal. A second replaces the ‘flat rate’ with a three-tier, modulated value for each material. And a third ‘traffic-light’ method had the potential to drive positive change in packaging design, while also reflecting the likely distribution of costs, based on the recyclability of individual packaging, said Valpak.

The EPR legislation is expected to be phased in from 2023, with the first payments made on, or before, April/May 2024.

Under the new system, the financial obligation will move to a single point in the supply chain. Obligated businesses – proposed in the consultation to be brand owners and manufacturers – will be responsible for financing the whole lifecycle of packaging waste, including local authority collections and the management of litter.

Skidmore concluded: “We stand on the brink of the greatest changes to the Packaging Waste Regulations in a quarter of a century. Put simply, this consultation represents the most important opportunity for everyone to have their say into how the system could operate for a long time to come.

“In the midst of a climate crisis, recycling can have a big impact, but the potential costs to producers are huge, and ensuring value for money for consumers will be critical.

The increase in packaging recycling resulting from the new system will generate a carbon reduction of 4.38 million tonnes between 2022 and 2032. The entire industry needs to make its voice heard, and Packflow EPR will help packaging producers to make an informed choice.”

Government called to prioritise tackling plastics at G7 Summit

On 27 May, 30 global figures called on the Government to make tackling the plastics crisis a priority at the G7 Summit, which is set to take place in Carbis Bay, Cornwall, from June 11 – 13.

In an open letter, TV presenter Chris Packham joined Nestlé, the Co-op, and Aldi, alongside parliamentarians and non-governmental organisations in urging the Government to place a global plastics treaty on the summit’s agenda. The letter was written by international organisation A Plastic Planet.

TV presenter Liz Bonnin backed the letter, alongside confectionery giant Nestlé UK & Ireland’s head of sustainability Dr Emma Keller and Aldi’s national corporate responsibility manager Hollie Clark. The letter was also signed by Iceland Foods managing director Richard Walker, The Co-operative Group’s environment manager Iain Ferguson, and Christina Dixon, of the Environmental Investigation Agency.

Currently, 300 million tonnes of plastic waste a year continues to be produced, while less than 10% of plastic had ever been recycled, with the rest sent to landfill, incinerated, or ending up as persistent pollution, A Plastic Planet claimed.

Sian Sutherland, co-founder, A Plastic Planet, said: “One man’s trash is another man’s problem. Only a globally aligned and binding strategy will stop the forecast Increase in plastic production and the inevitable pollution."

Plastics packaging tax

Her Majesty's Revenue & Customs has published a policy paper detailing how food and drink businesses can prepare for the new plastic packaging tax due to take effect from 1 April 2022. Menzies has outlined the main points. Business advice and accountancy firm Menzies has outlined the main points.

Who will be impacted? The tax will apply to packaging either manufactured in or imported into the UK, where the plastic used in its manufacture is less than 30% recycled. The tax also applies to packaging that contains multiple materials but has more plastic by weight than any other single substance.

Any businesses that manufacture or import more than 10 tonnes of plastic packaging over a 12-month period will need to register for the tax, even if they are not eventually liable to pay the tax. Crucially, this includes importers of packaging that already contains goods, for example plastic drinks bottles.

How much is the new tax? £200 per metric tonne of plastic packaging. The online service to register and pay is expected to become available on 1 April 2022.

How can businesses prepare? They should keep records of the packaging they manufacture or import - even if it consists of more than 30% recycled plastic. Businesses manufacturing or importing less than 10 tonnes of plastic packaging a year should still maintain records showing they are below the threshold.

Any invoices to business customers should include a declaration that Plastic Packaging Tax has been paid, if a company pays the tax as the manufacturer or importer of plastic packaging. Climate-conscious businesses should consider making changes to the manufacture or import of packaging now so that they include at least 30% recycled plastic and fall outside the new tax.

Deferrals and exemptions: If goods are being exported, a business can defer paying the tax for up to a year with no requirement to pay if the goods are exported within that 12-month period. There are some exemptions from the tax, regardless of how much recycled plastic they contain. These include packaging of medicinal products and transport packaging used in the safe delivery of goods into the UK, for example pallet wrap. However, plastic packaging used to transport goods within the UK will be liable for the tax.

Endoline Automation re-engineers tray erector for food pouch supplier

Endoline Automation has re-engineered a tray erector for a food pouch supplier, boosting performance. The customer, a global leader in the packing of food products into resealable pouches, was looking to automate the labour-intensive process of erecting up to 10,000 trays a week.

Packing a leading baby food brand into pouches, it required a system that could manage the construction of standard and taller sided trays to meet demand for shelf-ready packaging. Due to the height of the baby food pouches, they were unstable within standard sized trays, which made unpacking and shelf presentation inherently difficult.

The first, standard sized tray had four sides of equal height and was fitted with RRP pouch pack units to hold the products in place. The non-standard sized, taller tray featured three higher sides, with a shallow front for full product visibility.

Endoline, working with long-standing Scottish distributor, Murray Packaging, modified the tooling on the 501 Tray Erecting system to manage the forming of both tray sizes. Rigid in construction, due to the use of corrugated board, the trays also featured printed branding, so accurate and reliable forming was needed to ensure product presentation was maintained.

Using a hot melt glue to seal and secure the trays efficiently, the 501 Tray Erector is now forming up to 25 trays a minute. Offering 24/7 operation, it has been programmed for ease of tray size changeover, minimising downtime.

Proseal's new case packing system

Tray sealing specialist Proseal has launched a high-speed, fully automatic, patent-pending case packing system - Proseal CP3. Proseal promises the machine will offer customers a complete primary and transit packing solution. It combines efficient power consumption and a compact footprint with the ability to fill cases at up to 120 packs a minute.

It incorporates Proseal’s ProMotion tray infeed system, maximising throughput by using following motion and intelligent buffering technology to control the flow of trays, enabling them to feed continuously in the case packer without stopping.

The CP3 could handle pack formats ranging from trays, pots and sandwich packs, in materials such as A-PET, C-PET and board, said Proseal. It incorporates many of the features of the company's existing tray sealers. These include the ProTect user login and audit trail security system, which provides different levels of authorisation access for individuals, and full compatibility with the ProVision OEE and downtime analyser offering a real-time view of machine performance.

Set up and daily operation have been simplified with a menu-driven control panel using step-by-step prompts, error and status displays, and batch pack counter.

Options include additional crate fill and increased length of buffering conveyor for higher speeds. Crate delivery and discharge conveyors could be bespoke-designed to individual factory layouts and the CP3 could be fully integrated with complementary equipment, such as case erectors, existing create delivery systems, labellers and coders, Proseal claimed.

Packaging raw material costs (data and comments courtesy of Mintec)

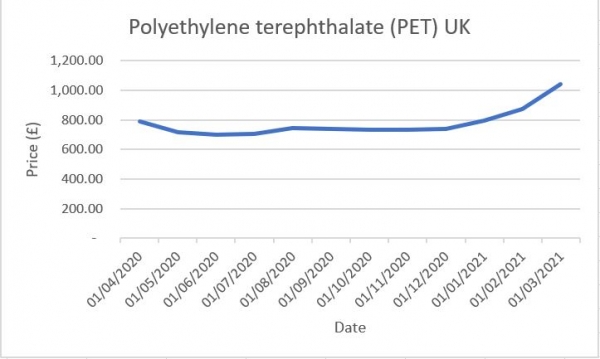

UK PET prices rallied during the first quarter of 2021, driven by limited supply and high feedstock prices. The March monthly average price reached the highest level since June 2019, at £1,039.80/tonne, up 19.4% month-on-month. The start of scheduled maintenance in spring is expected to further restrict supply during the second quarter of 2021. Also, with the high season for the beverage industry commencing due to the summer, PET demand is expected to increase, supporting prices further.

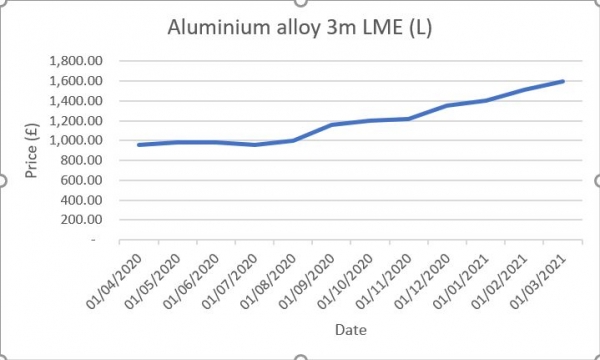

LME aluminium alloy prices soared in the first quarter of 2021, with the first quarter average price trending 19.5% above the previous quarter. The price reached a record level in March in terms of pound sterling, at a monthly average of £1,596.50/tonne (t), primarily driven by global demand recovery and turmoil in the shipping sector, due to the COVID-19 pandemic. In addition, China’s imports remained strong in the first two months of this year, with the country importing around 245,000t of primary aluminium and 141,000t of alloy.